Lathe Machine Gear

Lathe Machine Gear Specification

- Heat Treatment

- Carburized

- Product Name

- Lathe Machine Gear

- Hardness

- Hardened up to 55 HRC

- Material

- Alloy Steel

- Surface Finish

- Polished

- Color

- Metallic Grey

- Manufacturing Process

- Machined

- Corrosion Resistance

- Yes

- Usage/Application

- Lathe Machine

- Compatibility

- Universal for standard lathe machines

- Shape

- Round

- Gear Type

- Spur Gear

- Precision Level

- High Precision

About Lathe Machine Gear

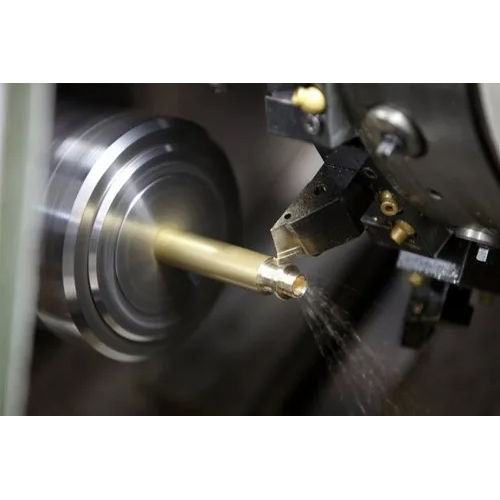

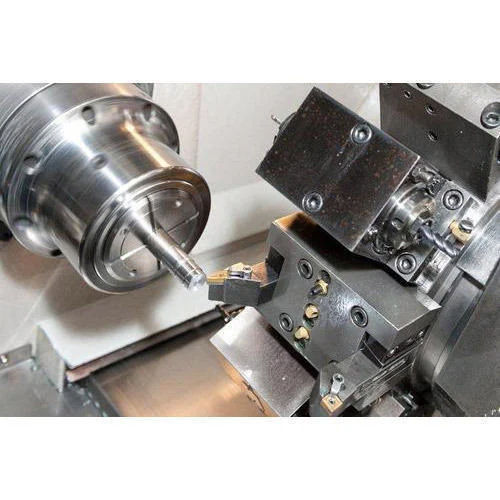

Presenting the Lathe Machine Gear, a champion in precision engineering manufactured by a venerable supplier in India. Crafted from elite alloy steel, this spur gear features a striking metallic grey finish, ensuring terrific corrosion resistance and a polished surface. Benefitting from advanced carburized heat treatment, its hardness reaches up to 55 HRC, guaranteeing superior durability. Universal compatibility with standard lathe machines makes this gear a special rate favorite among elite manufacturers seeking the lowest price without compromise. Choose reliability, strength, and excellence with our Lathe Machine Gear.

Versatile Application for Lathe Machine Gears

Lathe Machine Gear is expertly designed for high-precision applications in various industrial settings. Used primarily in lathe machines for shaping, cutting, and machining tough materials, these gears are ideal for manufacturing workshops, tool rooms, and fabrication units. The universal compatibility ensures it can be used in standard lathe machines, streamlining operations and enhancing equipment longevity across diverse production environments.

Export Markets, Packaging, and Reliable Supply

Our Lathe Machine Gears are exported to main markets including Asia, Africa, and Europe, supported by flexible payment terms. With stock ready for immediate supply, packing & dispatch are conducted with meticulous care using robust packaging to guarantee product integrity from India to your facility. Trust our dependable process for timely delivery, ensuring your operational efficiency remains uninterrupted.

Versatile Application for Lathe Machine Gears

Lathe Machine Gear is expertly designed for high-precision applications in various industrial settings. Used primarily in lathe machines for shaping, cutting, and machining tough materials, these gears are ideal for manufacturing workshops, tool rooms, and fabrication units. The universal compatibility ensures it can be used in standard lathe machines, streamlining operations and enhancing equipment longevity across diverse production environments.

Export Markets, Packaging, and Reliable Supply

Our Lathe Machine Gears are exported to main markets including Asia, Africa, and Europe, supported by flexible payment terms. With stock ready for immediate supply, packing & dispatch are conducted with meticulous care using robust packaging to guarantee product integrity from India to your facility. Trust our dependable process for timely delivery, ensuring your operational efficiency remains uninterrupted.

FAQ's of Lathe Machine Gear:

Q: How does the Lathe Machine Gear achieve high precision during operation?

A: The Lathe Machine Gear is manufactured through a machined process and features a polished surface finish, ensuring a high precision level essential for smooth, reliable performance in lathe machines.Q: What benefits does the carburized heat treatment provide to the gear?

A: Carburized heat treatment enhances the gear's hardness up to 55 HRC and offers terrific resistance against wear, significantly extending the lifespan and reliability of the product.Q: When is this gear recommended for use in lathe machines?

A: This gear is recommended whenever high-precision machining, shaping, or cutting tasks are required, especially in workshops, fabrication units, or tool rooms using standard lathe machines.Q: Where can the Lathe Machine Gear be supplied and exported?

A: As a manufacturer, supplier, and exporter based in India, we supply Lathe Machine Gears to various markets including Asia, Africa, and Europe, ensuring broad international reach.Q: What process is used for packing and dispatch?

A: Lathe Machine Gears are packed using robust materials to ensure protection during transit. Each order is dispatched promptly, with stock ready for immediate supply to meet your schedule.Q: How does the gear's corrosion resistance benefit users?

A: Exceptional corrosion resistance ensures the gear maintains its integrity and functionality even in demanding industrial environments, reducing maintenance costs and downtime.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free